Research

Patents

Procedure for obtainig ceramic granulated feedstock for thermal spraying apllications.

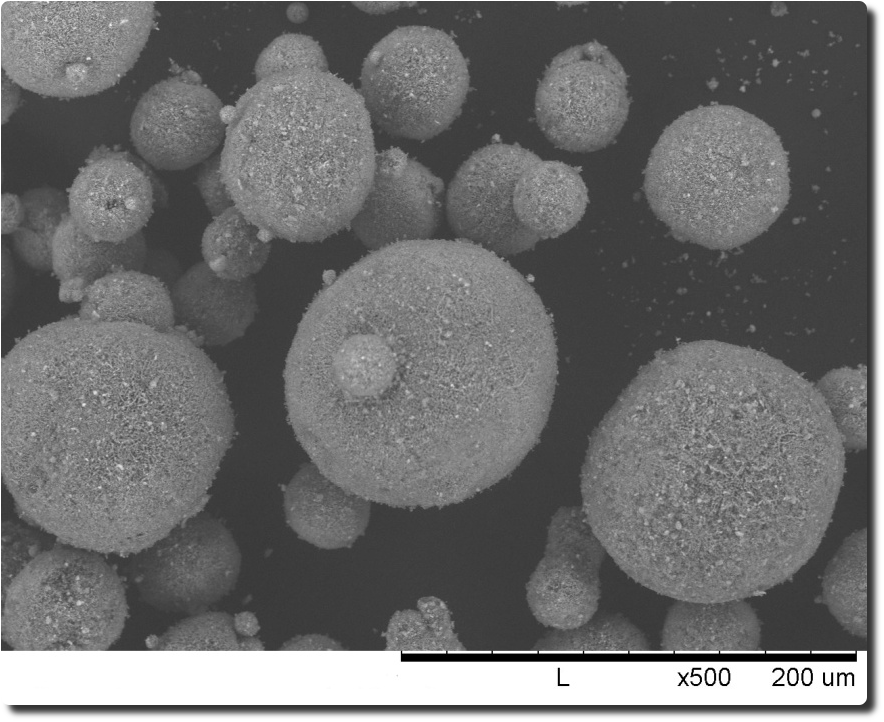

The feedstock material for thermal spraying equipment must fulfill different morphologic and particle size requirements to avoid clogging of the injection systems and to get homogeneous material avoiding heterogeneous deposited coatings. The present invention consists on a procedure for obtaining granulated feedstock powders from well dispersed ceramic powder suspensions that are sprayed in a cold medium and subsequently freeze dried for obtaining homogeneous ceramic granules with spherical shape and controlled porosity by means a compact equipment. The granules obtained with this technique can be mono-component or a homogenous mixture of different compositions. The yield of the process is up to of 90% of the granules with particle sizes within the sprayable range of 5 to 150 μm. The ceramic porous granules obtained with this procedure have the suitable characteristic to be used as feedstock in thermal spray coating techniques as Flame spraying, Plasma spraying or High Velocity Oxy-Fuel (HVOF) to obtain coatings for industrial applications that improve the properties and the working life of the substrate materials.

The feedstock material for thermal spraying equipment must fulfill different morphologic and particle size requirements to avoid clogging of the injection systems and to get homogeneous material avoiding heterogeneous deposited coatings. The present invention consists on a procedure for obtaining granulated feedstock powders from well dispersed ceramic powder suspensions that are sprayed in a cold medium and subsequently freeze dried for obtaining homogeneous ceramic granules with spherical shape and controlled porosity by means a compact equipment. The granules obtained with this technique can be mono-component or a homogenous mixture of different compositions. The yield of the process is up to of 90% of the granules with particle sizes within the sprayable range of 5 to 150 μm. The ceramic porous granules obtained with this procedure have the suitable characteristic to be used as feedstock in thermal spray coating techniques as Flame spraying, Plasma spraying or High Velocity Oxy-Fuel (HVOF) to obtain coatings for industrial applications that improve the properties and the working life of the substrate materials.

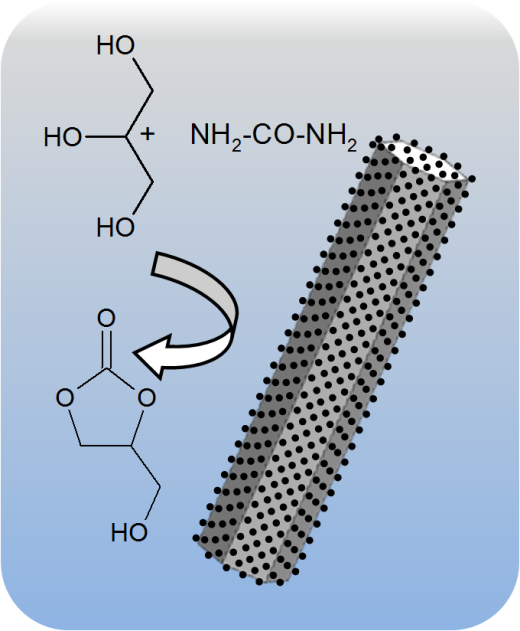

Dense and homogenous carbon nanotubes/silicon nitride ceramic materials.

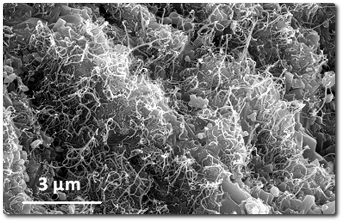

The present invention is related to a method for manufacturing carbon nanotubes (CNTs) containing silicon nitride matrix composites, and more particularly to the dispersion of the carbon nanotubes into the silicon nitride matrix and further densification to develop dense and homogeneous composites. CNTs contents up to 10 vol% were introduced into the composite. One of the main problems to fabricate homogenous CNTs/ceramic composites is the dispersion of CNTs into the matrix. An unsuccessful dispersion of the nanotubes within the matrix will lead to the formation of CNTs agglomerates and defects into the composite, causing a decrease on the properties of the material.

The proposed method comprises the dispersion of each component individually, as well as their mixtures, using for each step the most favourable dispersion process. The advantage of this method is that it avoids the use of organic dispersal agents and the later burning out step, then reducing the fabrication costs and limiting the introduction of additional impurities in the material. In addition, to get dense materials and to avoid carbon nanotubes degradation due to the high sintering temperatures, the spark plasma sintering technique was used with an appropriate design of the heating rate ramps. In the present invention, the maximum temperatures range between 1550ºC and 1650 ºC and the heating rates gradually decrease, as a function of temperature, from 133ºC·min-1 to 25 ºC·min-1. CNTs/silicon nitride components could be used in technological applications under strong demanding conditions where good thermo-mechanical and tribological properties are required, such as valves of diesel engines, thermal shock resistant components, bearings or cutting tools.

Inventors: Manuel Belmonte Cabanillas, Pilar Miranzo López y Mª Isabel Osendi Miranda

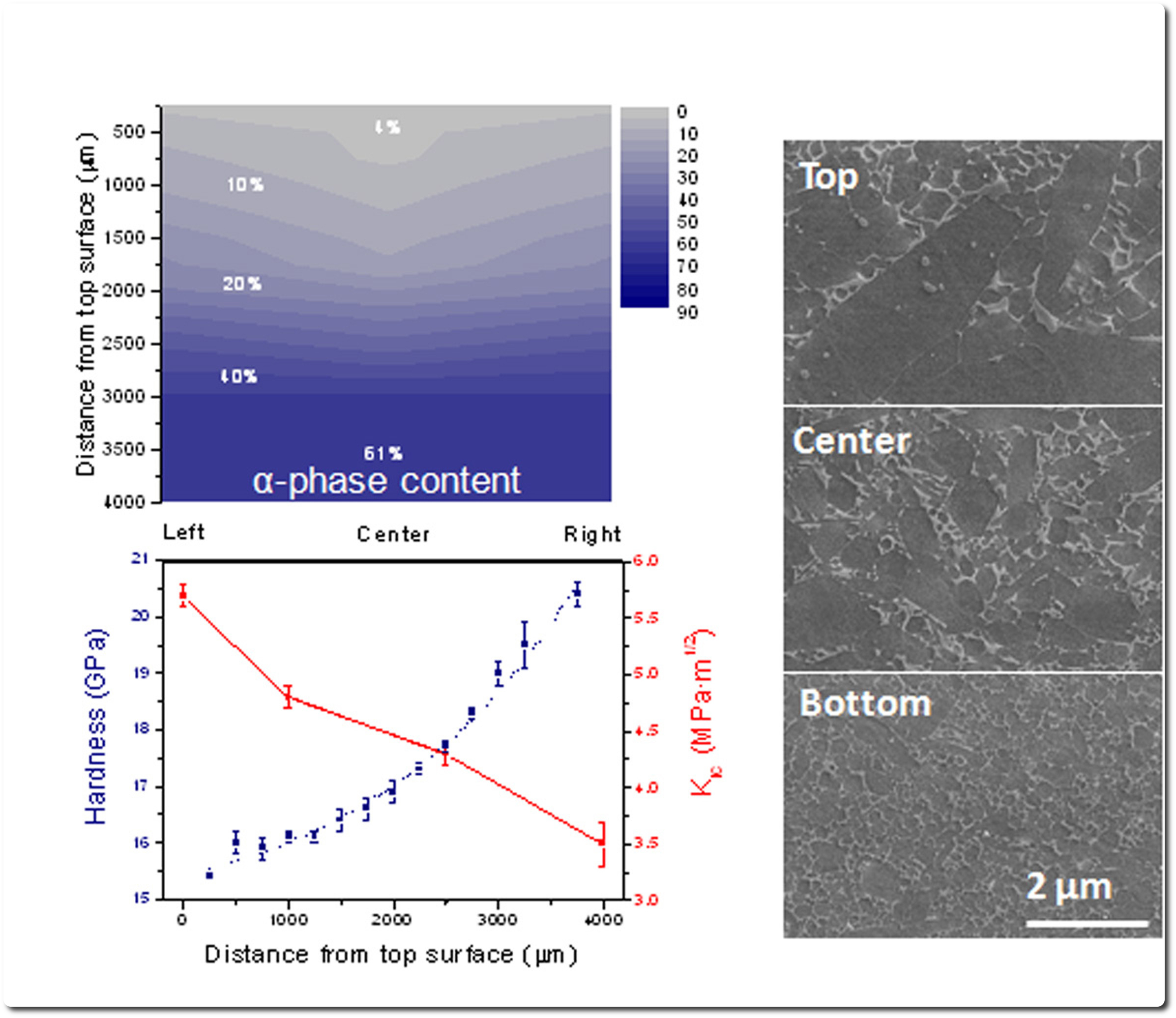

Continuos in situ functionally graded silicon nitride materials, method for manufacturating, properties and their applications.

The present invention is related to a silicon nitride material with a continuous gradient in their microstructural characteristics and properties, from one side of the ceramic component to the opposite one. A method for the in situ manufacturing of those functionally graded ceramic materials is described, which is based on the employ of a sole homogenous starting ceramic powders containing the starting silicon nitride powders plus the sintering additives, and developing a temperature profile within the powder compact during the sintering process using the spark plasma sintering technique (SPS). Those temperature variations are attained by changing the contact sections between punches and die placed into the SPS furnace, leading to different effective current intensities and, therefore, to different temperatures. The main advantage of this method is the in situ manufacturing process of the functionally graded material, which greatly simplify the transfer of the process to a mass production. In addition, the development of a continuous gradient would reduce the nucleation of stresses within the component, compared to layered processed materials, increasing its reliability under operating conditions. These functionally graded silicon nitride materials could be used in technological applications where good thermo-mechanical and tribological properties are simultaneously required, for instance, cutting tools, valves or bearings. They can also be used as substrates with a porosity gradient where carbon nanotubes were grown. This device can be used as catalysers or membranes.

Inventors: Manuel Belmonte Cabanillas, Jesús González Julián, Pilar Miranzo López y Mª Isabel Osendi Miranda

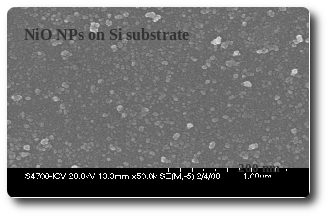

Dry dispersion of nanoparticles

One of the main problems on working with nanoparticles is their trend to form strong, difficult to break agglomerates. Different techniques of de-agglomeration based on the use of surfactant molecules covering the particles or on liquid medium dispersions have been followed to avoid these agglomerations. Nevertheless, in these cases a change of the nanoparticles can take place due to the interaction between them and the surrounding medium. Groups of the ICV-CSIC and IMM-CSIC collaborate to develop and patent dry, low energy dispersion methods that permit to control the final agglomeration state of nanoparticles. The process involves the use of electrostatic and van der Wall forces to effectively disperse nanoparticles. The dry process takes advantage of the natural trend of nanoparticles to agglomerate in order to anchoring and supporting on different substrates. Thus the dispersion of a certain amount of nanoparticles is produced in a variety of material from inorganic salts, synthetic or mineral ceramic powders, organic powders, semiconductor powders. The dispersion on substrates is also possible and <50 nm coating of disperse nanoparticles was demonstrated. The low energy process allows preserving the morphology and nature of the particles that serve as support even in polymer type materials. A wider variety of nanoparticles are validating to be used and disperse by this patented technology. Effective dispersion is afforded for spherical, fibrous or laminar nanoparticles with the requirement that almost one of its dimensions must be <100 nm. The anchoring of dispersed nanoparticles allows their used in composites and nanocomposites in which the matrix material is used to support the particles. The process promotes the friendly and environmental industrial use of nanoparticles. Moreover, this technique has open new applications and properties, as the appearance of new proximity magnetic properties or the enhanced catalytic properties of nanoparticles dispersions. Inventores: José F. Fernández, Israel Lorite, Fernando Rubio-Marcos, Juan Jose Romero, Miguel Angel García, Adrián Quesada, María Soledad Martín-González, Jose Luis Costa-Kramer.

One of the main problems on working with nanoparticles is their trend to form strong, difficult to break agglomerates. Different techniques of de-agglomeration based on the use of surfactant molecules covering the particles or on liquid medium dispersions have been followed to avoid these agglomerations. Nevertheless, in these cases a change of the nanoparticles can take place due to the interaction between them and the surrounding medium. Groups of the ICV-CSIC and IMM-CSIC collaborate to develop and patent dry, low energy dispersion methods that permit to control the final agglomeration state of nanoparticles. The process involves the use of electrostatic and van der Wall forces to effectively disperse nanoparticles. The dry process takes advantage of the natural trend of nanoparticles to agglomerate in order to anchoring and supporting on different substrates. Thus the dispersion of a certain amount of nanoparticles is produced in a variety of material from inorganic salts, synthetic or mineral ceramic powders, organic powders, semiconductor powders. The dispersion on substrates is also possible and <50 nm coating of disperse nanoparticles was demonstrated. The low energy process allows preserving the morphology and nature of the particles that serve as support even in polymer type materials. A wider variety of nanoparticles are validating to be used and disperse by this patented technology. Effective dispersion is afforded for spherical, fibrous or laminar nanoparticles with the requirement that almost one of its dimensions must be <100 nm. The anchoring of dispersed nanoparticles allows their used in composites and nanocomposites in which the matrix material is used to support the particles. The process promotes the friendly and environmental industrial use of nanoparticles. Moreover, this technique has open new applications and properties, as the appearance of new proximity magnetic properties or the enhanced catalytic properties of nanoparticles dispersions. Inventores: José F. Fernández, Israel Lorite, Fernando Rubio-Marcos, Juan Jose Romero, Miguel Angel García, Adrián Quesada, María Soledad Martín-González, Jose Luis Costa-Kramer.

Polvo compuesto nanoestructurado fosfato de calcio-plata. Procedimiento de obtención y sus aplicaciones.

La presente invención lo constituye un polvo compuesto nanoestructurado fosfato de calcio-plata útil como antibactericida y/o fungicida, con una eficacia similar a la de productos comerciales y con una baja toxicidad. El segundo objeto de la presente invención lo constituye el procedimiento de obtención de dichos polvos compuestos nanoestructurados fosfato de calcio-plata, consistente en la preparación de fosfato de calcio nanométrico a partir de un procesamiento sol-gel y, a continuación, la deposición de nanopartículas de plata en su superficie. Este polvo nanoestructurado puede ser utilizado en la elaboración de una composición bactericida y/o fungicida útil como desinfectante universal para aplicaciones, por ejemplo, en implantes quirúrgicos, instalaciones de uso público alimentación, dental, pinturas, prendas de vestir y embalajes. Inventores: Díaz Muñoz, Marcos; Barba Martín-Sonseca, María Flora; Torrecillas San Millán, Ramón; Miranda Fernández, Miriam; Moya Corral, José Serafín; Esteban Tejeda, Leticia; Fernández Valdés, Adolfo; Malpartida Romero, Francisco y López-Esteban, Sonia

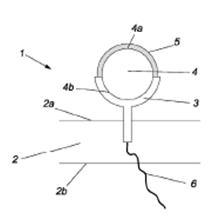

Electrodo para registro de señales bioeléctricas y su procedimiento de fabricación.

La Invención patentada presenta un dispositivo multielectrodo de tamaño pequeño, para el registro de las señales bioeléctricas en pacientes. Cada electrodo está formado por una cápsula de metal mecanizado rellena de un material composite orgánico-inorgánico preparado a partir de una matriz polimérica (pieza elástica porosa de látex), y un recubrimiento conductor (dispersión coloidal inorgánica), que actúa como captador de señales y que establece contacto con la cabeza del paciente. Esta tecnología está enfocada al mercado de biosensores y a empresas que puedan fabricar el electrodo a partir del prototipo existente. Inventores: Antonio Oliviero; Guglielmo Foffani; Vanesa Soto Leó; Eva Chinarro; José Ramón Jurado; Domingo Guinea; Berta Moreno; Eugenio Villanueva; Adolfo del Campo

La Invención patentada presenta un dispositivo multielectrodo de tamaño pequeño, para el registro de las señales bioeléctricas en pacientes. Cada electrodo está formado por una cápsula de metal mecanizado rellena de un material composite orgánico-inorgánico preparado a partir de una matriz polimérica (pieza elástica porosa de látex), y un recubrimiento conductor (dispersión coloidal inorgánica), que actúa como captador de señales y que establece contacto con la cabeza del paciente. Esta tecnología está enfocada al mercado de biosensores y a empresas que puedan fabricar el electrodo a partir del prototipo existente. Inventores: Antonio Oliviero; Guglielmo Foffani; Vanesa Soto Leó; Eva Chinarro; José Ramón Jurado; Domingo Guinea; Berta Moreno; Eugenio Villanueva; Adolfo del Campo

Polvo compuesto nanoestructurado fosfato de calcio-plata

Descripción de la invención: Un objeto de la invención lo constituye un polvo nanocompuesto o nanoestructurado, constituido por un fosfato cálcico, preferentemente con tamaño de partícula < 150 nm y que tiene adherida en su superficie nanopartículas de Ag, preferentemente < 50 nm. Este nanocompuesto pertenece, a título ilustrativo y sin que limite el alcance de la invención, al siguiente grupo: hidroxiapatita (HA), α-fosfato tricálcico (α-TCP),β-fosfato tricálcico (β-TCP) y/o mezclas de ellos, preferentemente HA. Otro objeto de la invención lo constituye un procedimiento de obtención del polvo nanocompuesto, que comprende las siguientes etapas:

- Preparación del fosfato cálcico nanométrico a partir de una ruta de procesamiento sol-gel.

- Deposición de nanopartículas de plata en la superficie del fosfato cálcico.

- Otro objeto de la invención lo constituye el uso del polvo nanocompuesto en la elaboración de una composición bactericida y/o fungicida útil como desinfectante universal para aplicaciones pertenecientes, a título ilustrativo y sin que limite el alcance de la presente invención, al siguiente grupo: implantes quirúrgicos, instalaciones de uso público -sanitarias y hospitalarias, transporte, etc.-, alimentación, dental, pinturas, prendas de vestir y embalajes -alimentos, farmacéuticos, dispositivos médicos. Imágenes obtenidas por microscopía electrónica de transmisión (TEM) mostrando A) las nanopartículas y morfología del fosfato cálcico, hidroxiapatita (HA), sinterizado B) las partículas de plata distribuidas sobre el HA C) detalle magnificado de una nanopartícula de plata, negra, adherida.

Inventores: Díaz Muñoz, Marcos; Barba Martín-Sonseca, María Flora; Torrecillas San Millán, Ramón; Miranda Fernández, Miriam; Moya Corral, José Serafín; Esteban Tejeda, Leticia; Fernández Valdés, Adolfo; Malpartida Romero, Francisco y López-Esteban, Sonia.

Trabajos relacionados:

- Synthesis and Antimicrobial Activity of a Silver- Hydroxyapatite Nanocomposite

- Marcos Díaz, Flora Barba, Miriam Miranda, Francisco Guitián, Ramón Torrecillas and José S. Moya

- Hindawi Publishing Corporation

- Journal of Nanomaterials Volume 2009, Article ID 498505, 6 pages

- doi:10.1155/2009/498505

Catalysts hierarchically organized by dry an nano-dispersion method.

Researchers from the Institute of Catalysis Petrochemicals (ICP) and the Institute of Ceramics and Glass (ICV) develop a new patent for obtaining catalysts hierarchically organized by dry an nano-dispersion method. The present invention is related to a process for preparing catalysts by nanodispersion and anchoring of nanoparticles or “clusters” with nanometric size, less than 100 nm, on supports with a micrometric or sub-micrometric size using a dry dispersion process at low energy. The catalysts prepared at room temperature are distinguished by the apparition of new nanoparticles/support interfaces capable of generating reactive surfaces, which favor high catalytic activity and selectivity. Thermal treatment of these catalytic systems causes the formation of stable crystalline species generating catalytically inactive interfaces by reducing the number of free active sites.

Researchers from the Institute of Catalysis Petrochemicals (ICP) and the Institute of Ceramics and Glass (ICV) develop a new patent for obtaining catalysts hierarchically organized by dry an nano-dispersion method. The present invention is related to a process for preparing catalysts by nanodispersion and anchoring of nanoparticles or “clusters” with nanometric size, less than 100 nm, on supports with a micrometric or sub-micrometric size using a dry dispersion process at low energy. The catalysts prepared at room temperature are distinguished by the apparition of new nanoparticles/support interfaces capable of generating reactive surfaces, which favor high catalytic activity and selectivity. Thermal treatment of these catalytic systems causes the formation of stable crystalline species generating catalytically inactive interfaces by reducing the number of free active sites.

Inventors: FERNÁNDEZ LOZANO, José Francisco; RUBIO MARCOS, Fernando; CALVINO CASILDA, Vanesa y BAÑARES GONZÁLEZ, Miguel Ángel.