Research

Research Lines

L1: Ceramics and Glasses for Energy, Environment and Transport:

- SL1: Bulk ceramics and coatings under severe working conditions.

- SL2: Electrochemical applications of materials (Elamat).

- SL3: Ceramic materials for solid oxide fuel cells.

- SL4: Glasses, glass-ceramics and sol-gel materials for a sustainable society (GlaSS).

Research Line L1

Ceramics and glasses for energy, environment and transport.

This research line is focused on the design, development and characterisation of ceramic and glassy materials in topics related to energy, environment and transport applications. These are the principal areas in which numerous projects have been carried out in the last decade in relation with ceramic, glass and energy industrial sectors and other final users of these materials. Activities related with materials working under stringent conditions, such as high loads, high temperatures, corrosive atmospheres, friction and wearing are developed and applied to technological systems such as gas turbines, engines, spatial vehicles, fusion reactors, etc. Another key issue is the development of materials and components for energy devices as fuel cells (PEMFC, SOFC, IT-SOFC), Li-batteries, photovoltaic solar systems and nuclear plants. These subjects come together with protective and environmentally friendly anticorrosive coatings, mesostructure coatings with photocatalytic activity for abatement of water or gas pollutants and solar cells, ceramic gas-separation membranes or nano glass-ceramics with photonic applications. One main objective is the increase of the efficiency of systems with a simultaneous reduction of their environmental impact, for example by increasing process temperatures in turbines and engines and/or reducing the weight of components and heat losses. Energy saving is a related and key target considered which is tackled by different approaches, from industrial glass furnaces and processes to solar and heat control in buildings and transport.

Sub-line SL1

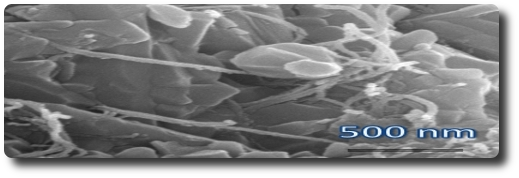

Bulk ceramics and coatings under severe working conditions.

This research subline is backed by the Technical Ceramics group, which is part of the Ceramics Dept of ICV. Activities in this research subline relates with materials working under stringent conditions of diverse kind, such as high loads, high temperatures, corrosive atmospheres, friction and wearing conditions. These events are common in many technological systems such as gas turbines, engines, spatial vehicles, fusion reactors, etc. One main objective is the increase of system efficiency without overlooking environmental impact, for example by increasing process temperatures in turbines and engines. The reductions of engineering components weight and heat losses associated to friction between parts are targets of this sub-line as well. The objective is the increase of system efficiency, for example by increasing process temperatures in turbines and engines. The reductions of engineering components weight and heat losses associated to friction between parts are targets of this subline as well.

Sub-line SL2

Electrochemical applications of materials.

The research subline (group) forms part of the Glass Department of the ICV. The group has been working for more than 30 years in the field of electrochemical and electrocatalytic processes involved in energy and environmental applications, and are pioneers at the national level on solid oxide fuel cells (aSOFCs). The importance of the group on the international stage is reflected through heavy involvement in European Union Framework programs requiring scientific and technological excellence. International cooperation also includes participation in joint collaborative projects and bilateral agreements. Joint publications with international centres accounts for 50% of the group article output. The internationalization of the group is further reflected by the profile of its members, which includes a non-national permanent scientist and three other non-national employees in the perioad 2003-2008. Scientific research is additionally funded by national public funds (National R&D plan, regional programs etc.). The technological focus of the group is supported with private and public technology-based projects (PETRI) and private contracts. In the period 2003-2007, one licensed patent has been granted and three have been solicited. Training of personnel is an important component of the group remit, including PhD theses, training courses and visits by foreign researchers and students. The group activity involves the design, development and characterisation of electroactive materials and components for electrochemical devices. Energy and the environment have been the principal areas in which most projects have been developed in the last decade. Materials and components are developed for polymer electrolyte membrane fuel cells (PEMFCs), solid oxide fuel cells (SOFCs) and ceramic gas-separation membranes. In the last five years, much activity has also been devoted to bioceramic electroactive materials for the adherence, survival and growth of neurons and other biomedical applications, including cancer therapy.

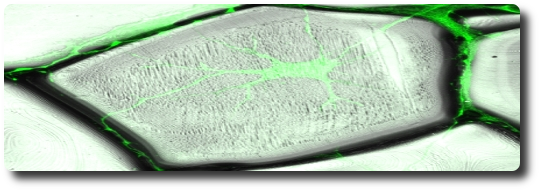

Sub-line SL3

Ceramic materials for solid oxide fuel cells.

During the last years, the study of ceramic materials used in manufacturing of Solid Oxide Fuel Cells (SOFC), is becoming a priority research among the scientific community. The main reason is the importance of the development of alternative ways to generate electrical energy, substitutive of pure thermal ones, in order to improve the efficiency, and overcome cost problems, scarcity of fossil fuels, and, most important, environmental problems. The study of SOFC has, consequently, a certain tradition. The interest in this type of devices is increasing with time, and nowadays their importance is such that, at national and European level, thematic nets are created to join efforts to reach technological objectives that lead to overcome some problems that still limit a massive use of SOFC. One of the novel interest lines is to prepare SOFC that can supply medium powers for distributed and mobile applications, such as automotive, air conditioning, housing, etc., working at moderate temperatures, with lesser demand of infrastructure. The application of this subline is basically oriented to the progress in the knowledge of the technology of the IT Solid Oxide Fuel Cells, (600º-800ºC), to the improvement of its energetic yield and to the enlargement of its mean life, with the subsequent economic impact on industry areas such as gas, electric generation, basic equipment and automotive and building as final customers. It is intended to use the previous experience, obtained with previous projects, on the preparation of nanometric and nanostructured dense layers of ionic conductors of Ce1-xBxO2-y (B=Sm, Gd).

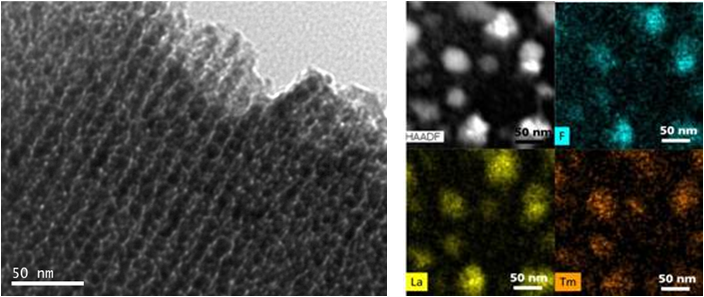

Sub-line SL4

Glasses, glass-ceramics and sol-gel materials for a sustainable society (GlaSS).

The sub-line is focused on topics related to glass, glass-ceramics and sol-gel materials from basic research up to applications in the industrial glass sector and other final users of glassy materials. Topics connected to energy and environment research are the aim of most projects developed in the last 10 years. Different materials and components for fuel cells (PEMFC membranes, sealing glasses and glass-ceramics for MCFC and SOFC), solid electrolytes for Li-batteries, low temperature sealing of systems in solar energy devices and nuclear plants, come together with protective and environmentally friendly anticorrosive coatings, mesostructure coatings with photocatalytic activity for abatement of water or gas pollutants and solar cells, nano glass-ceramics with photonic applications, and energy saving, an important issue with different approaches, from industrial glass furnaces to solar and heat control glasses for buildings. The general objective of this sub-line, is the design, processing and characterisation of glasses, glass-ceramics and sol-gel materials, going from the structural features to properties (optical, mechanical, chemical, thermal, electrical, etc) and applications. The research activity can be summarised in two methodological approachs:

- Glasses and glass-ceramics produced by melting:

- including tight sealing for high temperature applications as MCFC and SOFC, low temperature sealing with high chemical resistance, nitrided phosphate glasses for solid electrolytes of Li-batteries, controlled crystallisation processes, nanostructure glass-ceramics for photonic applications, modification of melting process for energy saving and lower emissions in glass furnaces.

- Sol-gel materials for energy and environment:

- including protective antioxidant coatings of composites, anticorrosive and functional coatings on metals and alloys, nanostructure films with corrosion inhibitors, bioactivation of metallic alloys for prosthesis, mesostructure coatings with applications in photo- catalyst and solar cells, inorganic and hybrid membranes for PEMFC, components for totally solid Li-batteries.

Research Line L2

Advanced processing technologies for structural and multifuncional ceramic materials and systems.

The line name refers to its focusing research in advanced processing technologies for both structural and multifunctional ceramics. The line gathers together three sub-lines with different ceramic materials and applications. The research activities in each sub-line are conducted within a classical approach of processing-structure-microstructure-properties relationships in which a high degree of specialization and a high international recognition have been already reached. The design, processing and properties evaluation are the key points to develop ceramic materials having technological relevance in the traditional and innovative industrial ceramic sector. The sub-lines have in common the tailoring of properties thorough improved ceramic processing and microstructure control. The basic knowledge is the basis in which the sub-line strengthens their technical skills. The large expertise in phase equilibrium diagrams, structural analysis, colloidal processing, shaping, microstructural development and properties, among others, allows the sub-lines to afford the study of a large variety of ceramics with specific properties. Bioceramic, electroceramics, functional, refractory, structural and traditional ceramic applications takes advantage of the capabilities of the line An increasing collaborative work among the sub-lines will work in the direction of reduce the differences in research funding and knowledge transfer actions, as well as the average research age and the sub-line size. The nanoparticles, nanocomposites and nanostructured ceramics capture the general attention of the line because they offer an important field of opportunities for understanding the main chemistry and physical parameters to promote new properties. Based on the understanding and control of new properties the line will take advantages to emphasize the knowledge transfer.

Sub-line SL1

Phase equilibrium diagrams of systems with ceramic interest. application to materials design and preparation of bioceramics and high temperature structural ceramics.

This research sub-line is developed in the Group for more than 40 years. The research activities of the group are fundamentally supported on the Theoretical and Experimental Study of Phase Equilibrium Diagrams, research area of basic interest in which the group is a pioneer in our country. This sub-line is dedicated to increase the basic knowledge in the thermodynamics, synthesis, processing, properties and service performance of ceramic materials. Nowadays, the group is the only one with this profile in Spain. Researches related to phase equilibrium diagrams of high temperature ceramics are conducted in the group since more than 40 years ago. Works in the field of bioceramics for bone engineering and guided bone regeneration, which applied the knowledge on Phase Equilibrium Diagrams, were started in 1991. The group cumulates more than 10 years of experience in the use of techniques based on diffraction of synchrotron and neutron radiation for real time studies of solid state reaction and transformation mechanisms. The scientific results have allowed the Group to be granted with basic projects funded by national and regional R&D programs for the design, formulation and preparation of new materials. Besides, applied research, oriented to solve technological problems of the industry (ceramics, refractories, glass, cement, steel, energy, etc.) is carried out with the support of public technology-based projects (CDTI, PROFIT, PETRI). The international relevance of the group is illustrated by its continuous involvement in the Framework Programs of the European Union which demands scientific and technological excellence from the participants. International actuation includes, as well, participation in bilateral agreements with European Union and Ibero-American countries. More than 50 % of the papers published by the Group have been done in collaboration with researchers of foreign institutions. The international character of the group activities is further reflected in the staff, which comprises a foreign permanent Intermediate Specialist Technician and three foreign employees. Training and formation of human resources is another important concern of the group. Spanish and foreign students conduct their PhD Thesis, Master Degrees, training courses and research stays under supervision of the members of the Group. The singularity of this group also implicates its participation in consulting and technical assistance in the fields of ceramics and refractories.

Sub-line SL2

Micro and nanostructured functional ceramics.

The Ceramic for Smart System Group possess a large experience in ceramic processing of functional ceramics which properties are based on complex micro and nanostructures. The specialization of the group is founded on the knowledge of physic and chemistry phenomena associated to interphases in ceramics. The research activity in the last years crystallize by the development of concepts as particle surface modification that originated the studies of grain growth control, grain boundaries engineering and nanostructure ceramics. Recently these knowledge resources were translated to the nanoparticle and nanocoating fields where the new class of Interphase Magnetism arises. From a technical analysis, the capability of the group members to establish correlations between the classical triad processing-micro(nano)structure-properties allows the group to obtain information to design new functional materials. The knowledge and technology transfer experience of the group powered the basic research studies and allows the line to pursuit the translation of new materials into industrial devices and applications.

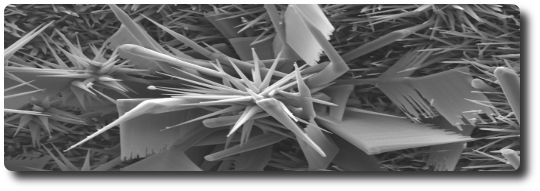

Sub-line SL3

Innovative colloidal processing technologies.

This sub-line focuses the manufacture of advanced ceramics with tailored microstructures focusing properties. All kinds of applications (energy, photonics, structural, magnetic, electronics, biomaterials, etc), are envisaged since all of them share identical issues and problems with regard to shaping and sintering processes. Special attention is given to the relationships between shaping and microstructure in order to enhance the properties, focusing on the nanoscale and microscale development of microstructure and the production of multimaterials and/or multifunctional systems. Innovative colloidal processing technologies for the production of defect-free bulk bodies, coatings and laminates of a broad variety of materials, including oxides and non-oxide ceramics, as well as metals to formulate ceramic-ceramic and ceramic-metal composites are in focus.

Research Line L3

Ceramics and glasses with social and industrial impact.

The line “Ceramics and glasses with a social and industrial impact” will develop at highest level, research on materials with traditional applications or wide implantation, but also with new and severe demands, in the industrial and cultural sectors of society. The scope of this line extends towards two research areas; “Archaeometry and Heritage of Ceramics and Glasses” and “Conventional Technologies for New and Eco-Friendly Products”. Archaeometry deals with the scientific approach to the analysis of ceramic materials in historic artifacts with an eye in the conservation of our Cultural Heritage. The characterization of ceramics and glasses to identify their key features, raw materials and manufacturing process is a necessary starting point of knowledge for the authentication, suitable protection and restoration of the material elements of our Heritage. Even more, Archaeometry provide the essential elements to establish the origin, the evolution through time and the historical meaning of the goods which constitute our Cultural Heritage. Research in conventional technologies responds to the social demands of new and eco friendly products capable of reducing energy consumption, increase the life cycle of products, as well as decrease pollution through the use of recycled materials. This issue has been mainly carried out in vitreous materials with special characteristics developed for traditional (frits, enamels, floor tiles, etc.) and advanced applications (solar glasses, eco friendly pigments, etc.,) to obtain new coatings for decreasing energy consumption, surface cleaning, etc., and in composite materials in which use of recycled materials as well as waste decreasing were the main objectives.

Sub-line SL1

Archaeometry and heritage of ceramics and glasses.

One of the most marked changes in the development of Social Sciences has been the recognition of the role that the study of antique materials plays in the reconstruction of the historic and cultural context of civilizations. Because ceramics and glasses are virtually indestructible, they are found in the majority of archaeological sites dating from the Neolithic beyond today and they are the most feasible remains of past ages. Ceramics and Glasses Archaeometry have, therefore, been essential in the archaeological interpretation of sites and periods and have constituted a mayor focus in archaeological science studies during the last thirty years. Social demands of this scientific approach to the analysis of materials in historic artifacts extend towards the conservation of Cultural Heritage. The characterization of ceramics and glasses to identify their key features, raw materials and manufacturing process is a necessary starting point of knowledge for the authentication, suitable protection and restoration of the material elements of Heritage. Even more, Archaeometry provide the essential elements to establish the origin, the evolution through time and the historical meaning of the Cultural Heritage goods. Including in the Instituto de Cerámica y Vidrio actions, Archaeometry and Heritage sub-line offers to Society not only a rigorous and contrasted analysis of ceramics and glasses with the most advances techniques, but also the scientific and technological knowledge which allows to explore and recover the evolution of past methods of production and their projection in the present and future developments.

Sub-line SL2

Conventional technologies for new and eco-friendly products.

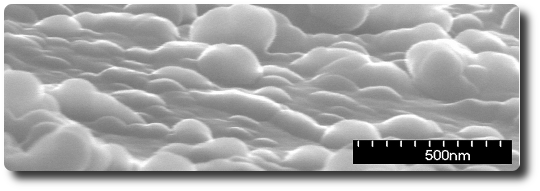

oday, research in conventional technologies is mainly focused on new and eco friendly products capable to reduce energy consumption, to increase life cycle of products, as well as decreasing pollution by means of using recycling materials. This sub line has been working since almost fifteen years ago developing different projects with very different Spanish companies. In the last five years this sub line has been mainly financed by means of the Spanish Industry. Research has been mainly carried out in vitreous materials with special characteristics developed for traditional (frits, enamels, floor tiles, etc.) and advanced applications (solar glasses, eco friendly pigments, etc.), for obtaining new coatings to decrease the energy consumption, surface cleaning for example and, in composite materials in which the use of recycled materials as well as decreasing of waste were the main objectives. On the other hand, this sub line has also carried out basic research in order to develop new materials like silicon oxycarbide materials by means of the sol-gel method and modify and characterize the surface energy of different materials. A lot of processes are produced by means of surface reactions. Then the knowledge of the surface (energy, nanoroughness, surface active sites, etc.) should give enough information in order to design both new materials and industrial processes. Modification of the surface has been carried out by means of design of products at molecular level such as sol-gel process as well as hybrid materials.